navigation

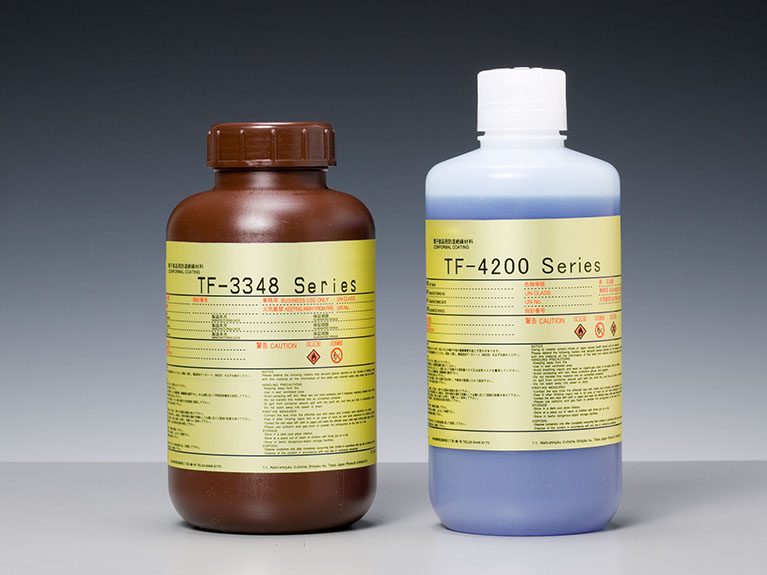

日本Hitachi Chemical日立可剥蓝胶TF-4200EB-452/TF-3348

日本Hitachi Chemical日立可剥蓝胶TF-4200EB-452/TF-3348

TF-4200EB-75

About the product

Resonac’s silicone-free insulation coating materials protect the connections of display peripheral circuits and prevent electrode corrosion caused by moisture absorption, thereby contributing to higher device reliability.

Merits

Protects circuits from moisture with low moisture permeability.

Low ionic impurities and high insulation reliability.

Inhibits electrode corrosion even under high-temperature, high-humidity conditions.

Excellent workability with short curing time and repairability.

Selectable solvent volatilizing and UV curing types based on applications and curing processes.

Characteristics

(Measurement examples)

| Item | Unit | TF-4200EB-75 | TF-3348-100B | |

|---|---|---|---|---|

| Curing | - | Solvent volatilizing type | UV curing type | |

| Viscosity (25℃) | Pa・s | 0.4 | 1.7 | |

| Drying or curing conditions* | - | Dry-to-touch time: | UV-LED (365 nm): 300~350 mJ/cm2 | |

| Coating thickness | μm | 50~200 | 300 | |

| Viscoelasticity (25℃) | MPa | 20 | 26 | |

| Permeability (40℃/90% RH, 24 h) | g/m2 | 75 | 30 | |

| Ionic impurity | Cl- | ppm | 1.2 | 6.0 |

| Na+ | ppm | 2.1 | < 0.5 | |

*Curing conditions are recommended examples. Please check the coating conditions, curing devices, and environment.

Migration resistance

Resonac’s materials provide superior moisture-proof properties with no electrode corrosion detected even after 300 hours of exposure to high temperature and humidity.

Testing conditions

ITO electrode (line/space = 35 μm/15 μm)

Coating thickness: 100 μm

High-temperature, high-humidity conditions: 60℃ /90% RH, DC10 V applied

Observation of electrode corrosion in ITO electrode comb patterns

| Item | TF-4200EB-452 | Conventional product |

|---|---|---|

Electrode condition |  |  |

| No corrosion | Corroded |

Changes in insulation resistance

所有产品分类

所有产品分类

友情链接Link

友情链接Link